- Company

- Semiconductor Equipment RelatedThermo-electric Modules

- Automotive Related

- Semiconductor Equipment RelatedFerrofluidic Seals (FerroSeals)

- Semiconductor Equipment RelatedFine Ceramics Components

- Semiconductor Equipment RelatedMachinable Ceramics Components

- Semiconductor Equipment RelatedEB Components

- Electronic Device RelatedFerrofluid

- Other RelatedSaw Blade

- Other RelatedIndustrial Knives and Cutters

Industrial Knives

and Cutters

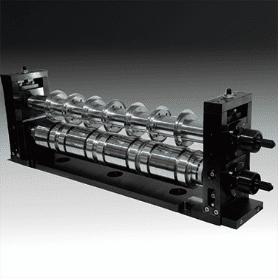

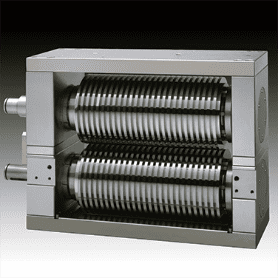

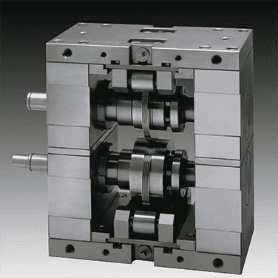

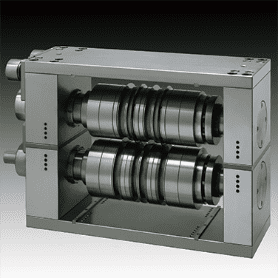

High precision parts and Cutter units

Good Design Award-winning holders for holding the upper blade of slitter knives, plate springs with unique technology, high-precision dies for LCD colour filters, guide rails and cutter units can all be manufactured to meet customer needs.

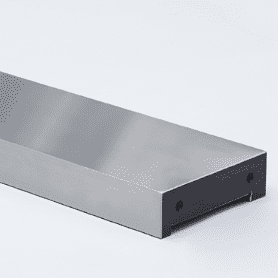

[Coating Die]

High-precision coating die made by using knife manufacturing technology cultivated over 90 years.

They are used in the coating processes of liquid crystal colour filters, optical films and magnetic tapes, and are the leading edge components of coating equipment.

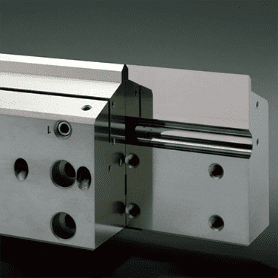

[Slide Way]

Slide Ways are rails used on the moving sliding surfaces of machine tools, injection moulding machines, forging machines, etc.

The hardened part can be multi-faceted and can be used for all types of sliding surfaces. For carburised products (material SCM), a hardened layer with an effective carburising depth of 1.2 mm can be obtained. All-steel products can also be manufactured.

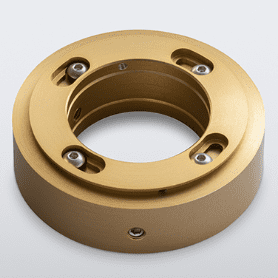

[Knife Holder & Plate Spring]

The holder is available in different specifications depending on the spring (coil spring or plate spring) set with the knife, but the plate spring specification is recommended to ensure stable contact pressure for improved cutting quality.

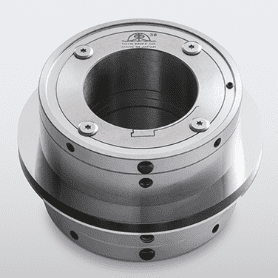

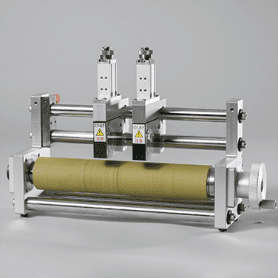

[Cutter Unit]

Our cutter units contribute to excellent reproducibility of slitting conditions and stable slitting quality.

We also offer laboratory units for research and development departments, which were developed from a different perspective from units for mass production slitters, for example, for “easy slitting to evaluate the performance of new materials” or “to find the best cutting method for commercialisation of newly developed materials.

Product Line

Machinery parts

-

Coating die

-

Slide way

Knife parts

-

High precision

movable holder -

Quick holder

(Standard, Bellock type) -

Preset holder

(Standard, Bellock type) -

Preset holder for

removing the middle part

(Standard, Bellock type) -

Plate Spring

Cutter unit

-

Cutter unit

(For Dish knife) -

Cutter unit

(For Gang knife) -

Ultra-fine width

cutter unit

(gang method) -

Cutter unit

(Spring gang method) -

Cutter unit

(Score-cutting method)